English

English

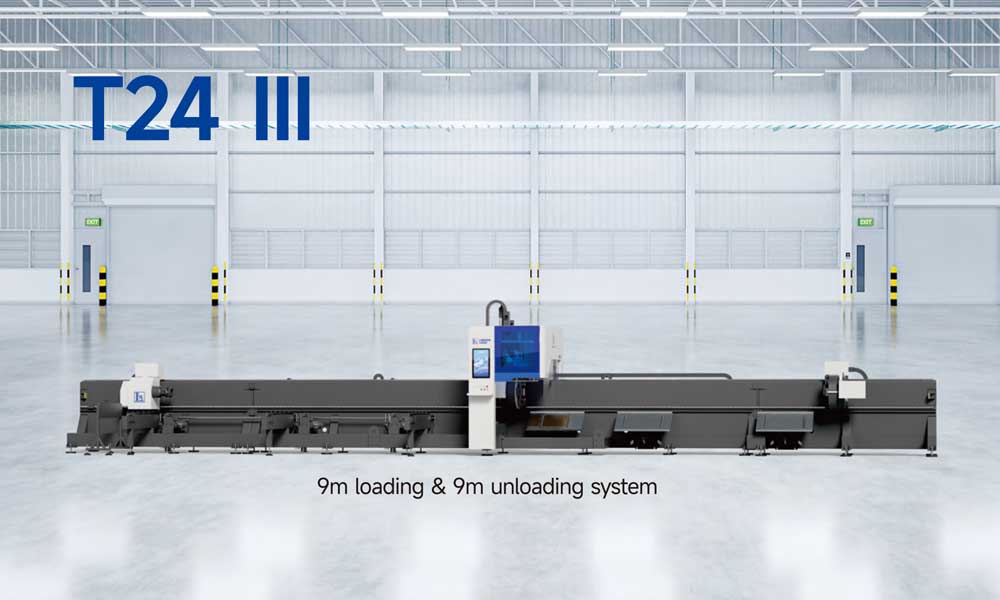

Advanced 3D Head Laser Tube Cutting Machines

Unlock the next level of metal fabrication with our T Series 3D Head Laser Tube Cutting Machines. Engineered for complex geometries and precision-demanding industries, the T Series integrates a high-performance 5-axis motion control system with a specialized 3D cutting head.Unlike standard 2D cutters, the T Series allows for seamless 45-degree beveling, intricate hole patterns on curved surfaces, and high-speed processing of diverse profiles including round, square, H-beam, and C-channel steel

Key Advantages of the T Series 3D Laser Cutter

5-Axis Linkage & 3D Beveling: The 3D laser head supports ±45° tilt, enabling perfect bevel cuts for weld preparation in a single pass, significantly reducing secondary processing time.

High-Speed T Series Performance: Optimized for industrial throughput, the T Series features rapid acceleration and high-accuracy positioning, ensuring your production stays ahead of schedule.

Multi-Chuck Support (Optional): Available with dual, triple, or four-chuck configurations to achieve "zero tailing" and superior clamping stability for heavy or long tubes.

Intelligent Profile Recognition: Effortlessly process not just standard pipes but also complex open profiles like I-beams and angle steel with integrated CAD/CAM software support.

H2: Precision Engineered for Demanding Industries (行业应用)

The T Series is the preferred solution for sectors where accuracy is non-negotiable:

Automotive & Shipbuilding: For exhaust systems, structural frames, and complex piping.

Steel Construction: Precise beveling for H-beams and architectural trusses to ensure seamless welding.

Fitness & Furniture: High-aesthetic, clean cuts on decorative tubes and ergonomic equipment frames.

Heavy Machinery: Robust processing of thick-walled industrial pipes.

H2: Technical Specifications & Customization

Our T Series comes in multiple power options ranging from 3kW to 12kW fiber laser sources (IPG/Raycus). With customizable bed lengths (up to 12m) and automatic loading systems, we tailor the machine to your specific workflow.

| Model | T35 | T28 | T24-6 |

| Power (W) | 3000-12000 | 3000-12000 | 3000-6000 |

| Cutting range (mm) | Round tube 40-350 ,Square tube 40×40-350×350 | Round tube20-280 ,Square tube20×20-280×280 | Round tube15-230, Square tube15x15-230x230 |

| Length range (mm) | 5500-6000 | 5500-6500 | 5500-6500 |

| Body size (mm) | 10000x3100x3000 | 10000x2800*3000 | 9620*2300x2600 |

| Body weight (t) | ≈8 | ≈5.5 | ≈4.5 |

| Maximum acceleration (g) | 0.4 | 1.0 | 1.0 |

| Cutting material | Metal materials such as carbon steel, stainless steel, aluminum alloy, copper and copperalloys (brass,purple copper), titanium alloy, galvanized steel tubes, etc. | ||

| Application industry | Steel structure,elevator industry, pipeline industry, wind power and other large pipe processing | ||