English

English

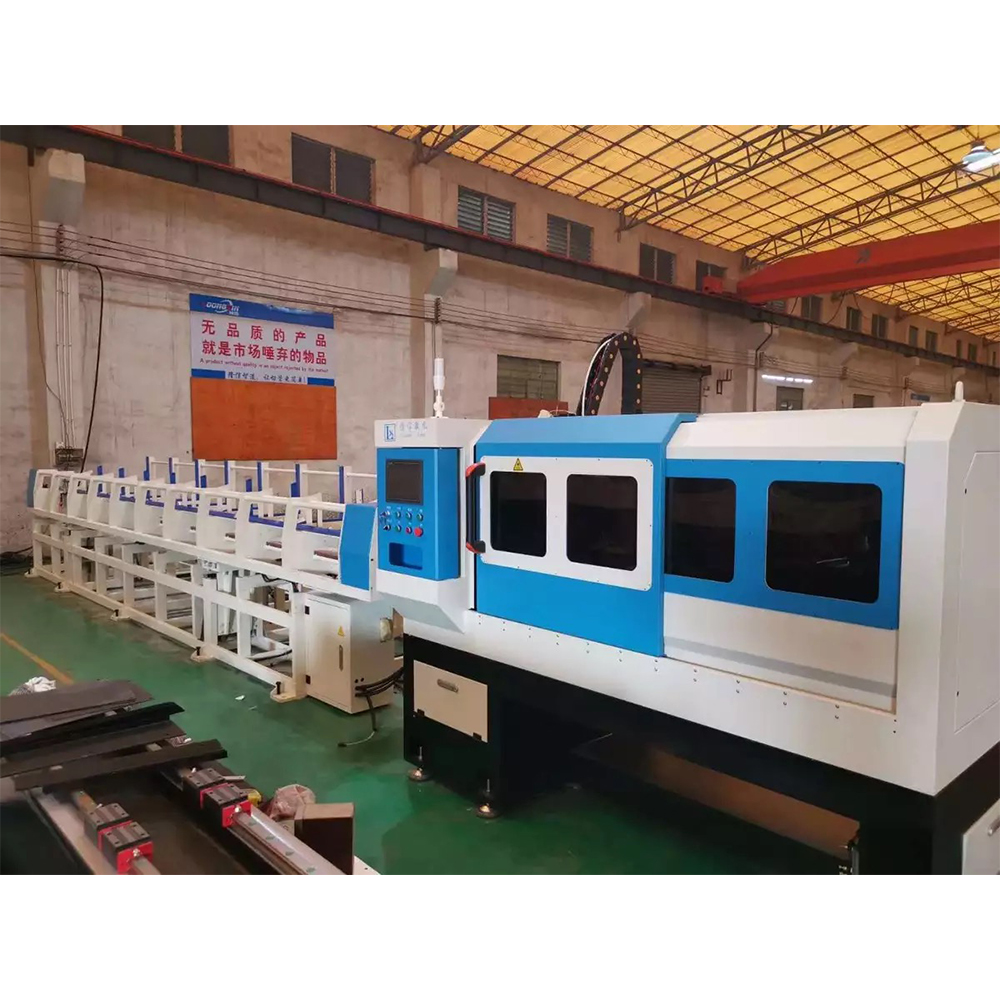

We should understand that the industrial use of stainless steel laser cutting machine should be said to be quite extensive, in many areas are fully utilized, it can be said that the development of the equipment in the market is very good. Therefore, we need more attention, especially in winter, cold weather is a great harm to the use of stainless steel laser cutting machine, we must pay attention to the winter stainless steel laser cutting machine antifreeze operation.

The antifreeze operation of stainless steel laser cutting machine in winter mainly includes:

First is the temperature, although the temperature of stainless steel laser cutting machine impact is not particularly large, but because many users will add butter to the silk pole, winter will definitely forget to clean up, resulting in every boot will not open. For example, the winter in the north is very cold, and the temperature in the studio is very low, although the oil machine will still not move. At this point we have to make sure that the temperature in the workshop is low enough to meet the refueling standards.

The second is cooling water, which needs to be replaced every day in summer to avoid exceeding the specified temperature, which many users ignore in cold winters, saying that cold water temperatures do not rise much. So many users often forget to change water, especially in winter, because the outside temperature is very low, the spindle motor heat is very difficult to feel. Therefore, we especially remind users that cooling water is a necessary condition for the spindle motor to work normally. If the cooling water is too dirty, it will cause serious harm to the motor and ensure the clean of cooling water and the normal operation of the pump.

There is also the problem of cleaning stainless steel laser cutting machines. Many users who have used stainless steel laser cutting machines think that stainless steel laser cutting machines need not be cleaned so clean, and sometimes they can clean them up properly. Because they think the stainless steel laser cutting machine itself will produce a lot of dust in the process of use, and if it is cleaned up every day, it will be very troublesome, which will easily damage the stainless steel laser cutting machine and reduce its service life. The correct approach should be to clean the table in time after work, which will facilitate the next job. Clean the guide rail and the material debris next to the guide rail to prevent debris interference from causing the machine to The card machine appears in the working process. Regular cleaning of the screw to prevent foreign bodies on the screw, the lead screw in the equipment is very important, it determines the accuracy of the machine, and the lead screw also plays an important role in the transmission process.