English

English

As the weather is getting hotter and more humid with rainy days, the temperature when the laser pipe cutting machine working is getting higher as well. The heat created during laser equipment operation will cause system failure sometime. In order to prevent laser tube cutting machines from malfunction in Summer, customers need to pay attention to machine maintenance & repairing.

The operating pressure of the cooling system increases in hot days during summer. We suggest to check the high temperature status of the compressed fluorine pressure chiller. The hot weather will speed up the deterioration rate of cooling water. We suggest customers to use conventional distilled water or deionized water for chillier operation, and clean & replace the water filter in the tank regularly (replacement period no more than 15 days in summer), so as to avoid high temperature alarm and large-scale impact in the pipeline caused by laser adhesion.

Under professional guidance, you could do as follow:

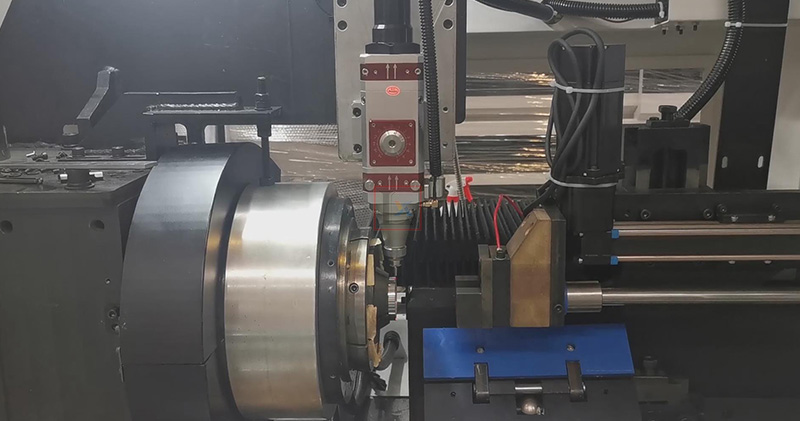

1.During laser pipe cutting machine maintenance, the guide rail should be cleaned from any dust & lubricated to ensure transmission action. Regular maintenance can ensure the machine with high accuracy of positioning & cutting in subsequent usage, so that the quality of your products could be confirmed.

2.Maintain the machine electric cabinet. The main dust of laser machine is the metal powder. We suggest to clean up electric cabinet regularly and check the air conditioner working status.

3.Clean up the exhausting fan. The exhausting van could accumulate a large amount of metal dust during long-term usage, eventually causing high noise during operation & affecting gas exhausting. Please clean up the exhausting fan when the exhaust is not smooth & sufficient.

The laser pipe cutting machine will serve you better through correct & regular maintenance. Within one year after purchasing LX-Laser tube cutting machine, we will provide customers with maintenance, after-sales repair, tuning and other services, including the maintenance of laser tube cutting machine.