English

English

First, compared to traditional processing equipment such as flame cutting, plasma cutting, and water cutting, the accuracy of laser cutting of metal plates is much higher. At the same time, as mentioned above, different materials may undergo slight expansion and deformation during processing. The laser cutting machine can be flexibly adjusted according to these deformations, which is also not achievable by many conventional processes.

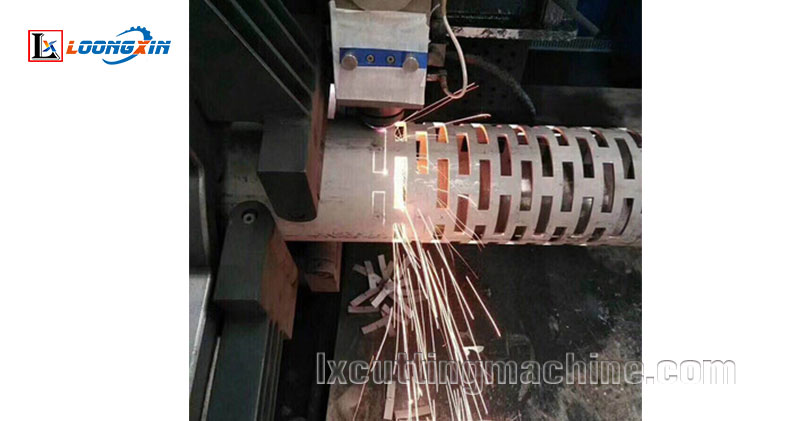

Second, the laser cutting machine cutting process is flexible, the performance of how to cut how to cut, it can cut any shape programmed in the stainless steel tube, the laser can complete the cutting requirements in any direction. The shape to be machined is designed using computer programming and can change shape quickly and flexibly. The high flexibility of the laser pipe cutting machine provides powerful technical support for more and more personalized processing, thereby reducing the number of molds used or even eliminating the use of molds.

Therefore, with the rapid growth of production and consumption of stainless steel pipes in China, rapid progress has been made in the processing technology of pipe materials. In particular, the emergence of laser pipe cutting machines has brought about leap-forward progress in pipe processing. As a special laser cutting machine, laser cutting machine is mainly used for laser cutting of metal pipes.