English

English

Laser (Light Amplification by Stimulated Emission of Radiation, abbreviated as LASER) refers to the light emitted by stimulated radiation. Einstein pointed out that if this radiation process is accompanied by an incident photon, the radiation will produce two photons with the same frequency, phase, polarization state and propagation direction as the foreign photon, and the newly generated photon will induce other radiation processes Double photons with the same characteristics are produced. This process is stimulated radiation. The stimulated radiation similar to nuclear reactions will finally obtain a collimated, monochromatic, coherent directional beam, which is the laser.

Laser processing is the main application direction of laser. Since its birth, laser technology has been widely used due to its excellent optical properties. After decades of development and technological progress, laser technology covers almost all major high-end manufacturing fields. On the one hand, as one of the core technologies of high-end manufacturing, laser technology plays an extremely important role in the fields of fine manufacturing and intelligent manufacturing. In the future, it will gradually replace and optimize the stock market of traditional industrial manufacturing technology; on the other hand , Laser technology is addressing the advanced process needs of some emerging high-growth fields (silicon carbide and other new semiconductors, photovoltaics, lithium batteries, etc.), and expanding the incremental market. From the perspective of laser application fields, according to Laser Focus World data, the proportion of global laser applications in the field of material processing in 2020 is close to 40%, and material processing is the direction with the largest proportion of laser applications.

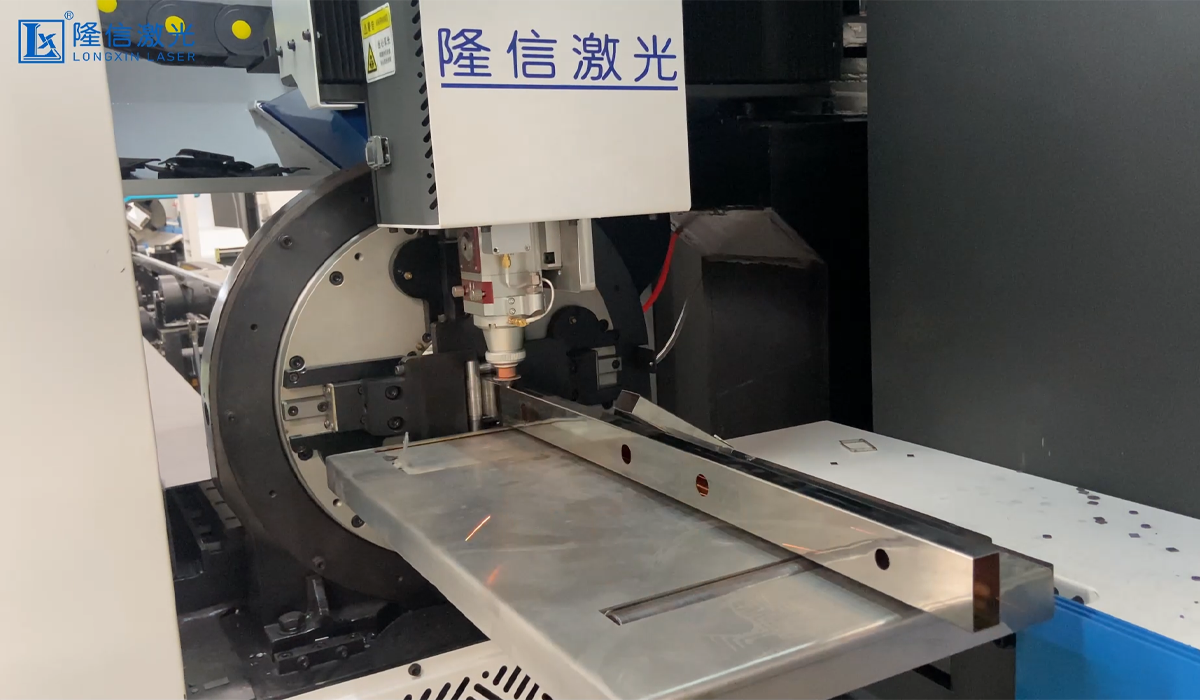

Laser processing has a wide range of applications. Laser processing technology is an innovation of traditional processing technology. Compared with traditional processing technology, it has the characteristics of cleanness, environmental protection, high precision and high degree of automation. Laser processing can achieve a variety of processing purposes, and can process a variety of metals and non-metals, especially materials with high hardness, high brittleness and high melting point; there is no tool wear, no contact stress, no noise, and no environmental pollution during the processing. Traditional lasers are mainly used for cutting, surface treatment, welding, marking and drilling etc. In recent years, precision laser manufacturing and service technologies have become increasingly mature, and laser technology as a whole has developed towards high frequency, high energy density, and high precision. The application range of laser processing equipment ranges from traditional large-scale manufacturing, such as sheet metal, automobile, aerospace industries, and gradually deepened into precision processing and manufacturing industries, such as automotive lightweight, power batteries, OLED, consumer electronics, semiconductors, etc.

In recent years, on the one hand, laser processing technology is gradually replacing the traditional processing technology in the field of macro processing by virtue of its advantages. On the other hand, with technological progress, it is gradually expanding to the incremental market of fine micro processing, which promotes the continuous growth of the market size of the laser industry. . According to Laser Focus World data, global laser sales revenue will increase from US$13.77 billion in 2017 to US$18.48 billion in 2021, with a CAGR of 6.1%. According to Laser Focus World data, the scale of China's laser market will increase from US$6.95 billion in 2017 To 12.9 billion US dollars in 2021, the CAGR will reach 13.2%.

As an advanced processing technology, laser processing has the characteristics of high processing precision, fast processing speed and small surface deformation compared with traditional mechanical processing, and can be deeply integrated with automatic control technology to realize the automation and intelligence of the production and processing process. In addition, there is no tool wear, low noise, and environmental friendliness during laser processing, which is in line with the development trend of green manufacturing technology. At present, laser processing solutions have become an important technical direction in the field of intelligent manufacturing. In the context of the gradual popularization of intelligent manufacturing and increasingly tightened environmental protection policies, laser processing equipment is gradually replacing traditional mechanical processing equipment. " to "light processing" trend is obvious.

As an advanced processing technology, laser processing is easy to combine with precision machinery, precision measurement technology and electronic computers, and can be automatically integrated with industrial robots to achieve high automation and intelligence in precision processing, thereby greatly improving processing efficiency. With the increasingly mature concept of intelligent manufacturing, laser processing equipment has gradually transformed from a single processing equipment to an automated production line with laser processing as the core and integrated with other functional components, and combined with machine vision, online detection and other technologies to achieve intelligent production. That is, laser processing equipment presents a trend of integration and intelligence.