English

English

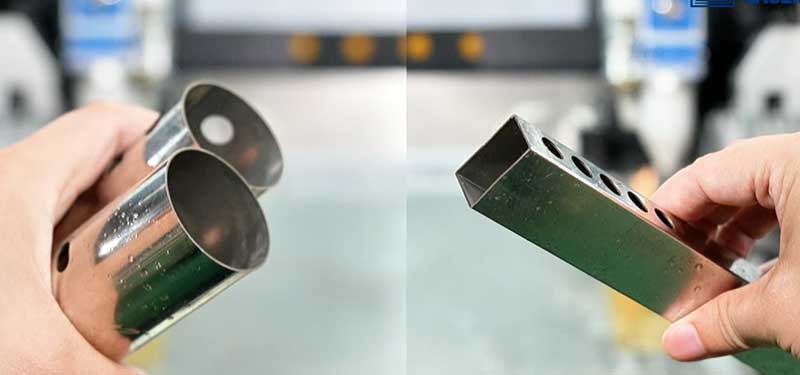

In the world of high-precision metal fabrication, a clean cut is only half the battle. For many industries—especially medical, food-grade, and automotive—the presence of internal slag (also known as dross or spatter) inside a laser-cut tube is a major quality failure.

When a fiber laser cuts through the top wall of a pipe, the molten metal is blown downward. Without the right intervention, this molten material adheres to the internal surface of the opposite wall.

If you are struggling with "the slag problem," this guide explores the most effective laser tube cutter slag removal techniques (internal) to ensure your production remains top-tier.

Why Internal Slag is a Major Manufacturing Hurdle

Internal slag isn't just an aesthetic issue; it’s a functional one.

1.Flow Interference: In fluid-handling pipes, slag creates turbulence and blockages.

2.Assembly Issues: Dross can prevent telescopic tubes from sliding or parts from seating correctly.

3.Safety Hazards: Loose slag can break off later, damaging sensitive machinery or causing injury.

4.Secondary Labor: Manual grinding or "poking" out slag is a massive bottleneck that kills your ROI.

Top Internal Slag Removal & Prevention Techniques

1. Anti-Spatter Fluid Injection (Prevention)

The most efficient way to handle internal slag is to prevent it from bonding in the first place. Many modern fiber laser tube cutters are equipped with an internal anti-spatter system.

How it works: A nozzle or rod sprays a biodegradable, oil-based, or water-based anti-spatter solution inside the tube before the laser begins the cut.

The Result: The molten metal hits the coated surface and slides off or remains loose, rather than welding itself to the inner wall.

2. Internal Suction and Vacuum Systems

For larger diameter tubes, a vacuum-assisted slag removal system is highly effective.

How it works: A vacuum extractor is synchronized with the laser head. As the laser cuts, the high-pressure assist gas (Oxygen or Nitrogen) pushes the slag down,

and the vacuum pulls the dust and micro-particles out of the tube instantly.

Best for: Dry cutting processes where liquid contamination must be avoided.

3. The "Water Curtain" or Flushing Method

Frequently used in high-end fiber laser systems, the water curtain acts as a physical barrier.

How it works: A stream of water or a specialized cooling liquid is pumped through the center of the pipe during the cutting process.

The Result: The liquid instantly chills the molten dross, solidifying it before it can bond to the metal. The flow of water then flushes the loose granules out the end of the tube.

4. Mechanical Brushing and Deburring

If prevention systems aren't built into your machine, post-process mechanical removal is the next step.

Hone Brushes: Flexible abrasive brushes (often called "dingleberry" brushes) can be run through the tube after cutting.

Sandblasting/Bead Blasting: For smaller parts, tumbling or internal bead blasting can strip away stubborn dross.

5. Assist Gas Optimization

Sometimes the secret to slag removal is the gas you use.

Nitrogen (High Pressure): Nitrogen "blows" the melt away more cleanly and prevents oxidation. While more expensive than oxygen, it significantly reduces the tenacity of the slag bond.

Frequency Modulation: Adjusting the laser’s pulse frequency can create a "cooler" cut, reducing the volume of molten material generated.

How to Choose the Right Technique for Your Shop

When deciding which internal slag removal technique to implement, consider the following:

Requirement Recommended Technique

High Volume / Automation Anti-spatter injection or Water Curtain

Cleanliness (No Residue) Internal Vacuum Suction

Thick-Walled Pipes High-pressure Nitrogen assist gas

Low-Budget Solutions Manual mechanical brushing

The ROI of Clean Internal Cutting

Investing in slag removal technology might seem like an added expense, but it pays for itself by:

Eliminating Manual Labor: Reducing the need for a secondary cleaning station.

Reducing Scrap Rates: Meeting the strict internal cleanliness standards of the aerospace and medical sectors.

Increasing Tool Life: Slag-free tubes prevent damage to downstream bending and flaring tools.

Conclusion

Internal slag is a byproduct of the physics of laser cutting, but it doesn't have to be a permanent part of your workflow. By implementing internal anti-spatter systems or vacuum extraction, you can produce "ready-to-ship" parts directly from your laser tube cutter

[Contact LX Laser today] for a quote on the most reliable compact laser pipe cutting solutions!