English

English

Compared with other welding technologies, the main advantages of laser welding are:

1. Fast speed, large depth and small deformation.

2. It can be welded at room temperature or under special conditions, the welding equipment is simple.

For example, when the laser passes through the electromagnetic field, the beam will not shift.

The laser can be welded in vacuum, air and certain gas environments.

It can be also welded through glass or materials that are transparent to the beam.

3. It can weld refractory materials such as titanium, quartz, etc.and weld heterogeneous materials with good results.

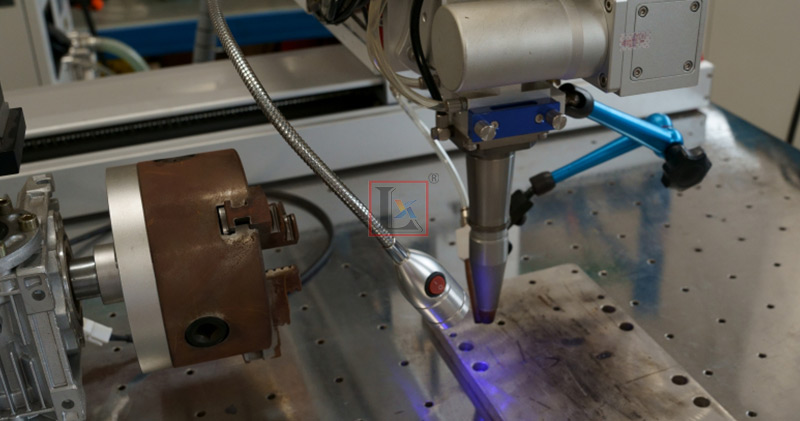

4. After the laser is focused, the power density is high.

When welding high-power devices, the aspect ratio can reach 5:1, up to 10:1

5. Micro welding can be used.

The laser beam can obtain a small spot after being focused and get accurate positioning, which can be used in the assembly welding of micro and small workpieces that are mass-produced automatically. (The smallest spot can reach 0.1mm)

6. It can weld difficult-to-access parts and perform non-contact long-distance welding, which has great flexibility.

In recent years, the use of fiber transmission technology in YAG laser processing technology,

The popularity of fiber continuous lasers have made laser welding technology more widely promoted and applied.

And it is more convenient for automated integration.

7. The laser beam is easy to realize the beam splitting according to time and space.

It can carry out multi-beam simultaneous processing and multi-station processing, which provides conditions for more precise welding.

However, laser welding has some limitations:

1. The welding parts are required to have high assembly accuracy, the position of beam on the workpiece must not be significantly shifted.

This is because after the laser is focused, the spot size is small and the weld is narrow, which is filled with metal materials.

If the assembly accuracy of the workpiece or the positioning accuracy of the beam does not meet the requirements, it is easy to cause welding defects.

2. The laser generator and related systems are with high cost. The one-time investment is relatively large.