English

English

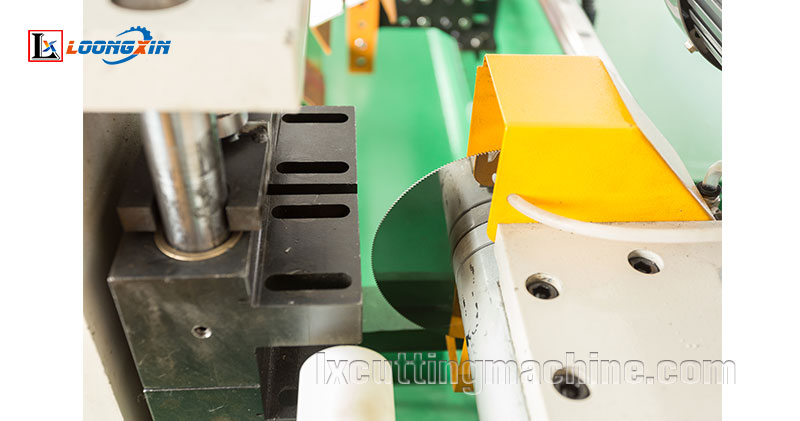

When the high-speed steel circular saw blade is in use, the general sawing is stable, the effect of cutting off will be better, and the service life will be longer. If it is found that sawing instability, such as severe vibration, how to deal with? The following is a brief explanation of the problem.

I. Bad equipment, causing sawing vibration

When it was discovered that high-speed steel circular saws were used for sawing, there was severe vibration. We should first check whether the equipment was in good condition. This problem was mostly caused by equipment or the saw blade was not installed correctly.

1. Vibration caused by sawing when the motor axially oscillates

2, the fixture is not clamped or the material is too thin, you can use a special fixture

3, high-speed steel circular saw blade is not installed correctly when installed, resulting in signs of loosening

4. The saw blade does not correspond to the material being cut or the model number of the equipment. This is a common-sense problem and should be checked again when using it.

The above are the most common causes of blade cutting instability of several factors, for different situations, using different methods to avoid, in strict accordance with the instructions for operation, before use must first check the equipment is good, regular cleaning and maintenance in order to enhance Sawing efficiency.

Second, high-speed steel saw blade caused by sawing vibration

There are several kinds of problems in this type of situation. One is that they are not used according to the regulations, or that the blade has been used for a long time, and then there is a quality problem when the saw blade is produced.

1. Sawtooth becomes blunt. This is a natural phenomenon because the saw blade is a consumable item and needs to be reground or replaced after a certain period of use. During use, we should regularly check the situation to ensure the quality of cutting.

2, the angle is wrong, there are many kinds of saw teeth, for different equipment and materials, need different tooth shapes

3, the surface roughness of the circular saw blade, such as large end-jump, if this situation, then remove the saw blade in a timely manner

4, there is a point that is cut off the material, if the bump is very serious, it will inevitably occur in the case of vibration when sawing, in this case, the general need to deal with the formation of anti-material flat, and then cutting

No matter what the problem is, the metal circular saw blade milling cutter must ensure its sharpness. After installation, it must be idling about 15 seconds to check that it is working properly before it can be used.