English

English

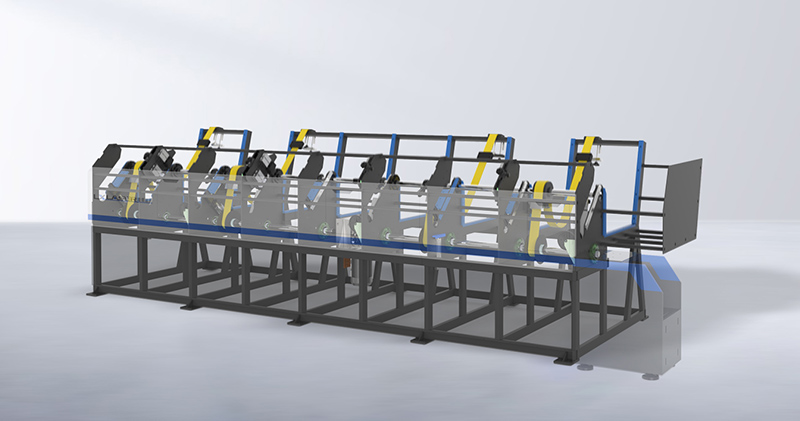

Ultra-rapid speed cutting, economical version fully automatic machine – LX-K6S

Ultra-rapid speed laser cutting, short tail material

- Compared with universal laser tube cutting machines, the cutting speed is 30% faster!

- Machine acceleration up to 1.5G!

- The minimum tail material length can be just 40mm!

Fully automatic bundle loading

- Skip production processes and minimize the labor costs and consumables

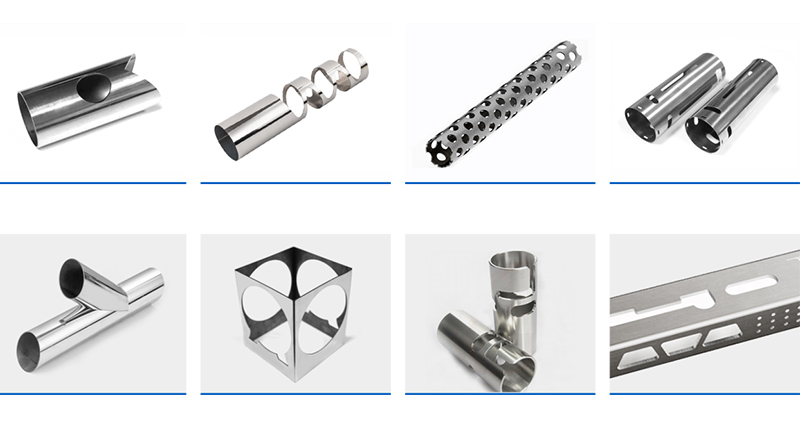

Multi-functional cutting

- Applicable types of tubes: Round, Square, Rectangular, Oval

- Applicable types of cutting: Holes cutting, Angle cutting, Arc cutting, Letters & patterns cutting…

- Applicable types of material: Stainless steel, Carbon steel, Galvanized steel, Brass, Aluminum, Copper…

- Ultra-rapid speed, smooth and burr-free cutting.

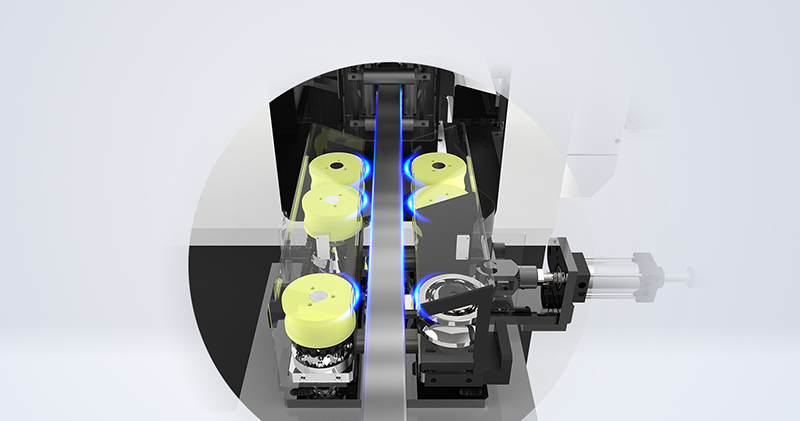

Simultaneously loading and cutting

- 6 feeding rollers clamp the pipe, feeding cycle does not need to be reset, reducing the waiting time and greatly improving the cutting efficiency

LX Self-developed system

- With United Kingdom RADTUBE nesting software, easy to operate, stable performance

| Model No. | LX-K6S |

| Outside Diameter | 15-60mm |

| Square Diameter | 15*15-60*60mm |

| Tube Length | 4000-6200mm |

| Laser Power | 1000-2000W |

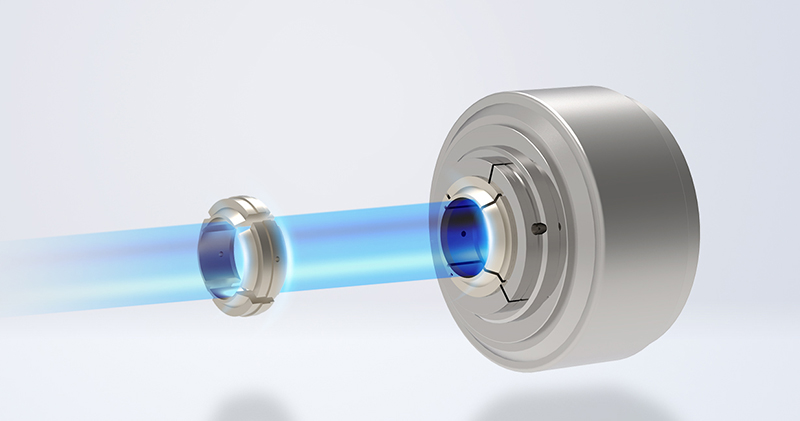

| Laser Source | MAX |

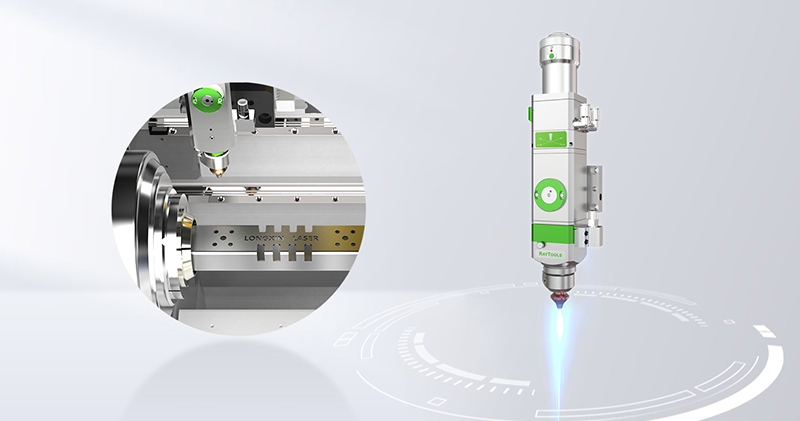

| Laser Head | RAYTOOLS |

| L*W*H (mm) | 9200*2000*1800 |

| Machine weight | 3.5 Tons |

| Tail material length | 40-60mm |

| Voltage | 380V 50Hz 3Phase (can be customized) |

| Control System | LX LASER |

| Air pressure | 1.6 - 3.0 MPa |

| Nesting Software | RADTUBE / United Kingdom |

| Servo motor & driver | DELTA / Taiwan |

| Reducer | China |

| Pneumatic system | AIRTAC / Taiwan |

| Electrical proportional valve | SMC / Japan |

| Electrical components | SCHNEIDER / France |

| Gear rack | China |

| Rail | China |

1. Does the machine have automatic lubrication system?

Yes, our machine has automatic lubrication system. You can set the lubrication time and interval time as needed.

2. How does the machine determine the center line of the tubing if the tube is slightly bent?

Our laser head has scanning function to check the tube bending degree and the control system will automatically compensates. You can also set in the system for it.

3. We have one pipe tube that is mid carbon content(SAE1020), diameter 10mm*1.25mm(wall thickness) , is this ok for machine?

Yes, this pipe is ok for our model LX-FL40. It is suitable for pipe diameter below 42mm, steel / stainless steel thickness within 3mm under 1000W laser power.

4. How many hours of working life has the laser? What is the spare part cost approximately?

Laser source life 100,000 hours (more than 20 years). Spare part is the protective lens and nozzle of the laser head. Each can use 2-5 months, we offer each 5pcs for spare and free of charge. For additional quantity, each cost 16USD/ pc.

5. Is there a difference between MAX / RAYCUS / IPG?

The quality of lasers made in China is gradually mature and stable. According to our testings, Max and Raycus are similar in performance. IPG is rarely used in the market within 6KW, unless customers concern on the brand and do not care about the cost. This is because IPG does not show obvious difference from the other two within 6KW power.The share of IPG lasers in China is also declining year by year, in 2018 was 48% and went down to 30% 2019. The share of Max and Raycus are similar, both about 20%.In addition, the laser source is only one part of the machine. Customers should pay more attention on the performance and efficiency of the whole equipment.

6. Regarding stabilizing electric transformer, for 220V 60hz e phase, how many KVA is required?

The transformer capacity is depends on the laser power. For laser power 1000W, it requires 40KVA.

7. PLC, has English or maybe Spanish language?

Our touch screen has both English and Chinese language. We can add Spanish or other language with your help for the translation.

8. Can we send you sample of our pipe in order for you to show us cutting of our material?

Yes, we always welcome customer send us their pipe for testing. Kindly send us pipe length ≥600mm, qty ≥ 3pcs for each size. The longer size and the more quantity the better.

9. What is the material loss every time laser cuts? I mean, when laser is cutting what is the length waste for every cut?

The laser cutting loss is very small, only 0.05-0.1mm/cut, while saw cutting loss would be about 2-5mm/cut.

10. After laser cuts, is the edge hardened by the laser temperature? Can we flare pipe easily without problem after cutting?

The hardening effects are different on different pipe materials. We suggest customers send us their tubes for testing and check the result.

11. Under what circumstances should I choose to use a laser machine?

If cutting quantity is more than thousand pieces per day, we suggest laser machine. As it has advantage on the cutting loss, operation cost(0.6USD/hour) and high efficiency(fast and no burr). In long term usage, laser machine can bring you more profits.

12. When can it cover the machine cost and gain profits for me?

According to our surveys, usually it would take about 0.5 to 1.5 years for our customers to cover the machine cost by the profits they obtained on the laser machine.