English

English

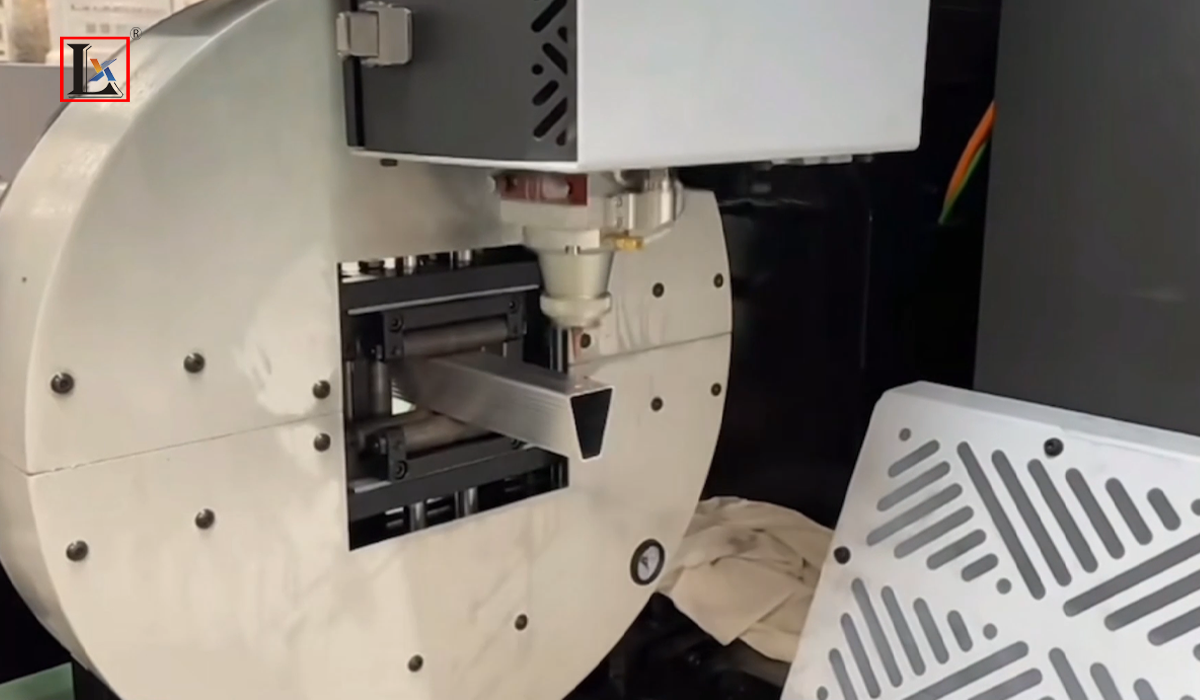

Nowadays, the requirements for pipe cutting effect are getting higher and higher, and many customers have turned to laser pipe cutting machines. So what problems do you usually encounter when using laser cutting tubes? We have summarized the three main problems and corresponding solutions.

1. The workpiece has burrs

The reason why the workpiece processed by the laser tube cutting machine has burrs: the upper and lower positions of the laser focus are incorrect, and the focus position test needs to be done, and adjustments are made according to the offset of the focus; the output power of the laser is not good, and it is necessary to check whether the laser generator is working Normal, if it is normal, check whether the output value of the laser control button is correct and adjust it; the cutting line speed is too slow, you need to increase the line speed during operation and control; the purity of the cutting gas is not good, you need to provide high-quality Cutting the working gas; the focus of the laser is offset, and the focus position test needs to be done, and adjustments are made according to the offset of the focus; the instability of the machine tool running for too long requires shutdown and restart at this time.

2. Processing small hole deformation

The small hole processed by the laser pipe cutting machine is deformed. This is because the machine tool does not adopt the method of explosive perforation when processing small holes, but uses the method of pulse perforation, which makes the laser energy too concentrated in a small area, and the non-destructive The processing area is also scorched, forming hole deformation and affecting the processing quality. At this time, we should change the pulse perforation method to the explosion perforation method in the processing program to solve it. The opposite is true for laser cutting machines with lower power. When processing small holes, pulse perforation should be used to obtain better surface finish.

3. Abnormal sparks appear

Abnormal sparks appear when the laser tube cutting machine is working, which will affect the processing quality of the cut section finish of the part. At this moment, when other parameters are normal, the following situations should be considered: the loss of the nozzle of the laser head, and the nozzle should be replaced in time. In the absence of new nozzle replacement, the gas pressure for cutting should be increased; the thread at the connection between the nozzle and the laser head is loose. At this moment, the cutting should be suspended immediately, check the connection status of the laser head, and re-thread the head.

The above are the common problems and solutions when using the laser pipe cutting machine. I hope to help you use the laser pipe cutting machine better and maximize the production efficiency.