English

English

In the high-stakes world of structural steel fabrication, precision and speed are the currencies of success. The traditional methods of cutting H-beams—involving band saws, drilling rigs, and manual layout—are becoming bottlenecks in modern production lines. Enter the Heavy Duty Laser Tube Cutter for H-Beam (12m), a technological powerhouse designed to handle massive structural profiles with micron-level accuracy.

Whether you are building skyscrapers, bridges, or heavy industrial machinery, upgrading to a 12m laser cutting system is not just an improvement; it is a transformation. This guide explores everything you need to know about these machines, from their technical capabilities to the ROI they deliver.

A heavy duty laser tube cutter is a specialized CNC machine capable of processing large-format metal profiles. Unlike standard tube lasers that handle small diameter pipes, these beasts are engineered to clamp, rotate, and cut heavy H-beams (as well as I-beams, C-channels, and rectangular tubes) up to 12 meters (40 feet) in length.

Powered by high-wattage fiber laser sources (typically 6kW to 12kW), they can slice through thick carbon steel flanges and webs in a single pass, performing complex cuts that would traditionally require three or four separate machines.

Key Technical Specifications to Look ForProduct Features

1.Side-mounted machine bed for stable and efficient operation

2.Precision square-hole chuck for a wider square-tube processing range

3.Follow-up support system to prevent tube sagging and ensure higher cutting accuracy

4.Zero tailing (under suitable cutting conditions)

5.Ideal for large tube processing: round ∅40–350 mm; square 40×40–350×350 mm; single-tube load capacity: 1000 kg

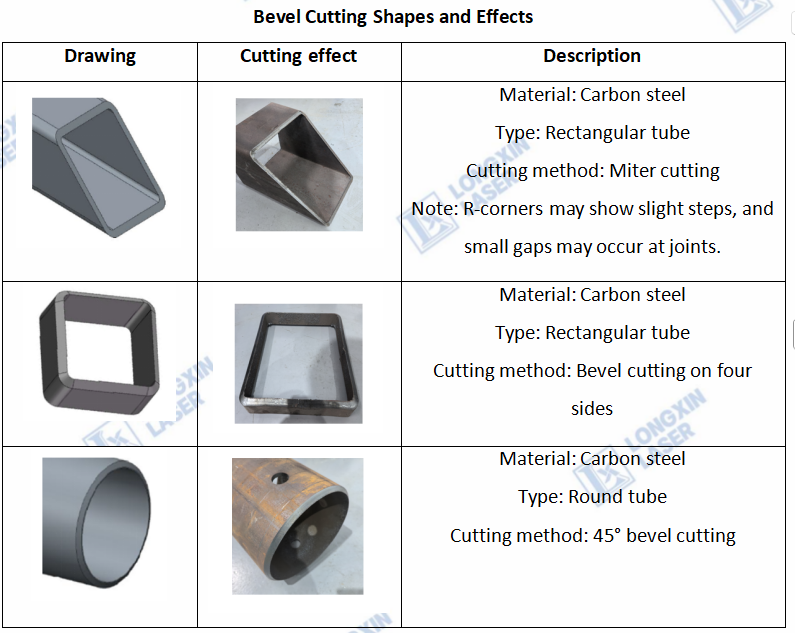

6.Supports bevel cutting up to ±45°

Laser Source: Maxphotonics /Raycus fiber lasers for stability.

Top Features of Modern 12m H-Beam Laser Cutters

To rank as a top-tier "heavy duty" machine, the equipment must offer more than just raw power. Look for these advanced features:

1. 3D 5-Axis Bevel Cutting

Standard laser cutters cut vertically (90°). However, structural steel often requires welding preparation. A 3D laser cutting head can tilt ±45°, This eliminates the need for secondary manual grinding or milling.

2. Precision Chuck System

The 365 full-stroke pneumatic chuck features a built-in cylinder and easy installation design. It performs clamping and releasing actions through side air intake, allowing full-range tube clamping for higher efficiency.

The four-jaw guide uses a rail-driven transmission mechanism to ensure excellent linearity and stability of the jaws. The chuck supports up to 1000kg per tube, with 0.05 mm repeat accuracy and 60r/min max speed (idle speed decreases with heavier tubes).

During tail-end cutting, the front chuck can move to avoid interference, allowing for ultra-short tailing (when the cutting layout is properly arranged).

3. Automatic Loading and Unloading

Handling 12-meter steel beams requires dangerous and slow crane work. High-end systems come integrated with automatic chain loading systems and conveyor unloaders. This automation reduces labor costs and significantly improves workshop safety.

The heavy duty laser tube cutter for H-beam 12m is indispensable in sectors where material integrity and fit-up accuracy are critical.

Application Industries: Steel structure, tower, shipbuilding, petroleum pipeline, engineering machinery, bridge engineering, special automobile, and laser processing services.

Applicable Materials: Carbon steel, stainless steel, and aluminum alloy tubes (square, round, and oval).

→→ →→ →→ →→ | ||

Are you ready to upgrade your production line?