English

English

Laser pipe cutting machines have revolutionized the cutting industry, making traditional cutting methods a thing of the past. Here's why laser pipe machines are replacing traditional cutting methods:

Superior Precision: Laser pipe cutting machines offer unparalleled precision and accuracy. The focused laser beam produces clean, precise cuts with tight tolerances, ensuring consistent quality and eliminating the need for secondary finishing processes. This level of precision is difficult to achieve with traditional methods like sawing, shearing, or manual torch cutting.

Versatility in Material Handling: Laser pipe machines can handle a wide range of materials, including metals like steel, stainless steel, aluminum, and non-metals like plastics. They are capable of cutting through various pipe thicknesses and shapes, accommodating complex designs and geometries. This versatility allows for greater flexibility in manufacturing and expands the range of applications.

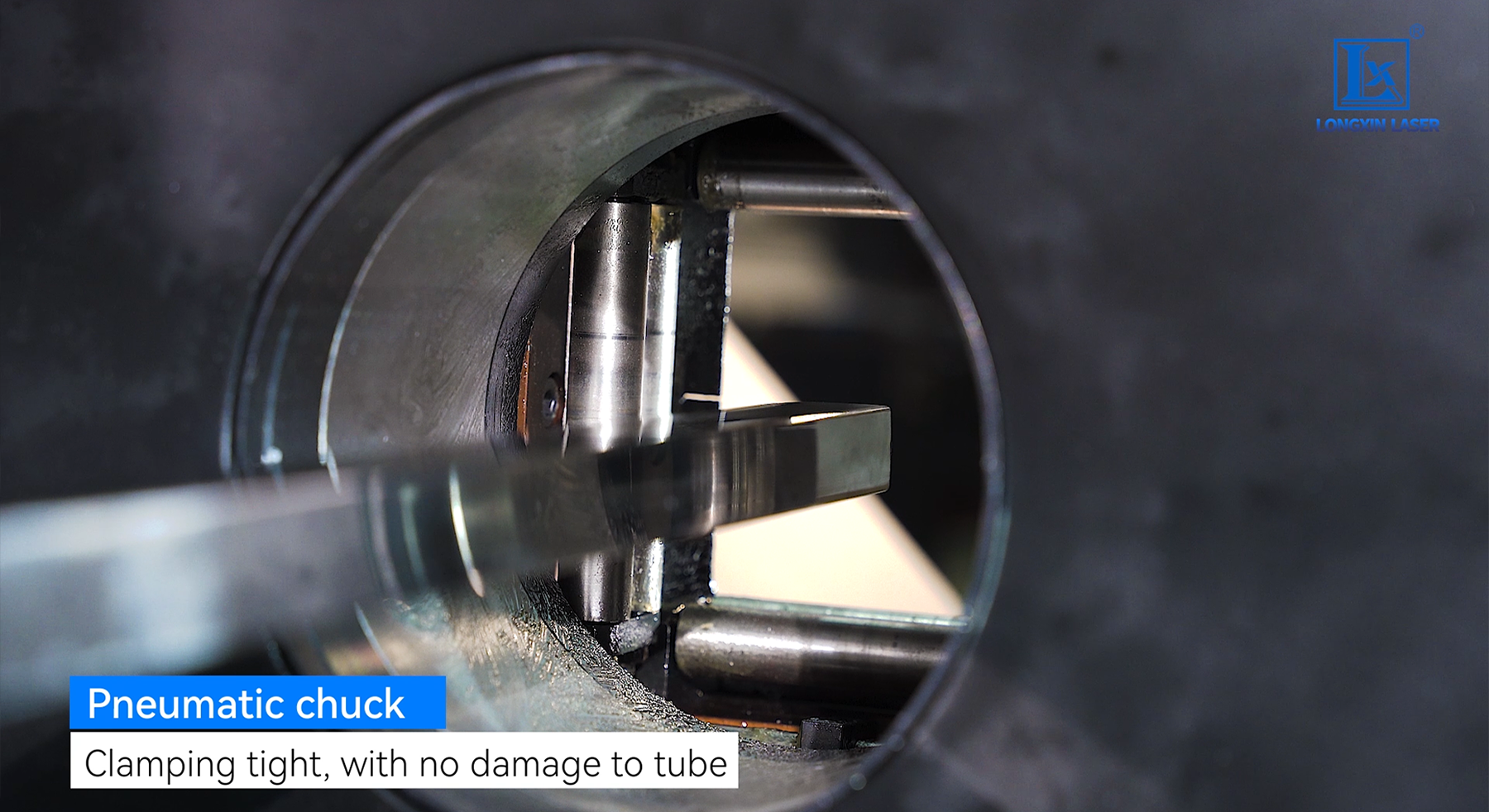

Increased Efficiency and Speed: Laser pipe cutting machines operate at high speeds, significantly reducing cutting cycle times compared to traditional methods. The non-contact nature of laser cutting eliminates the need for clamping or repositioning of the pipe during the cutting process, resulting in improved efficiency and faster production rates. This translates into shorter lead times and increased overall productivity.

Minimal Material Waste: Laser pipe cutting machines optimize material usage by employing advanced nesting algorithms. These algorithms intelligently arrange pipe designs on the stock material, minimizing waste and maximizing the number of parts cut from each tube. Traditional cutting methods often result in higher material wastage due to wider kerf widths and less efficient layout planning.

Enhanced Safety and Worker Protection: Laser pipe cutting machines prioritize safety in the workplace. With enclosed cutting areas and integrated safety features, they minimize the risk of accidents and ensure operator protection. Traditional cutting methods, on the other hand, may involve manual handling of sharp tools and expose operators to greater safety hazards.

Automation and Integration Capabilities: Laser pipe cutting machines can be seamlessly integrated into automated production lines, offering increased efficiency and reduced labor costs. They can be synchronized with material handling systems, robotic loaders/unloaders, and CAD/CAM software, allowing for seamless workflow automation. This level of integration enhances productivity and streamlines manufacturing processes.

Cost-Effective in the Long Run: While laser pipe cutting machines may require a higher initial investment compared to traditional cutting methods, they offer significant long-term cost savings. Laser cutting eliminates the need for tooling changes, reduces labor costs, and minimizes material waste. The precise cuts also result in higher material utilization and reduce the need for rework or scrap, ultimately improving the overall cost-effectiveness of the production process.

By adopting laser pipe cutting machines, manufacturers can enjoy superior precision, versatility, efficiency, and cost savings compared to traditional cutting methods. This technology represents a significant advancement in the cutting industry and enables manufacturers to meet the demands of modern production requirements.