English

English

CNC Full Automatic Pipe Hole Punching Machine LX-125-2

Features:

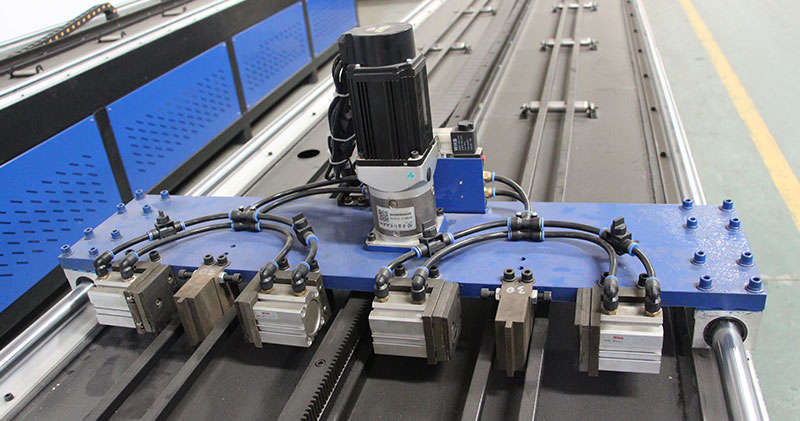

1. Servo motors control feeding

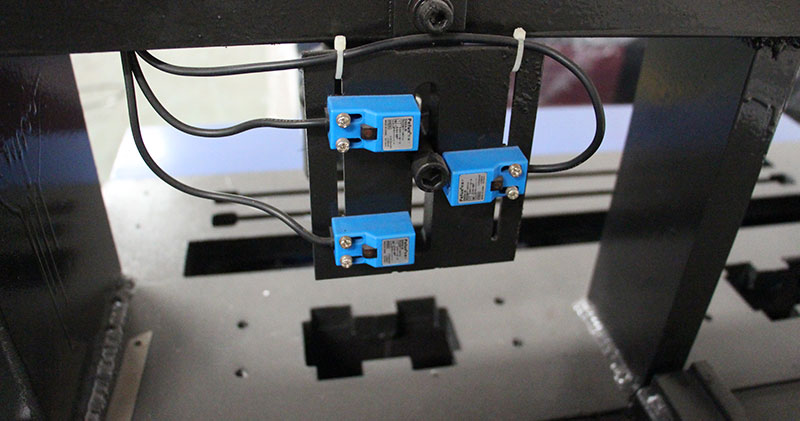

2. Sensors for punching on one side or both sides

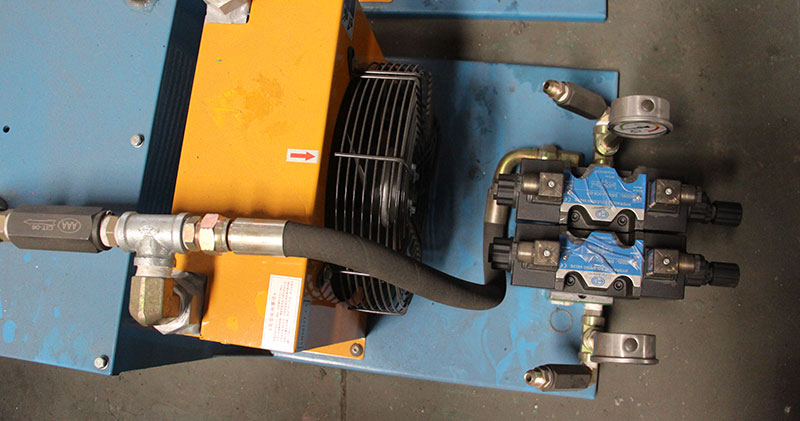

3. Solenoid valve, inner hole acid milling processing, no stuck valve

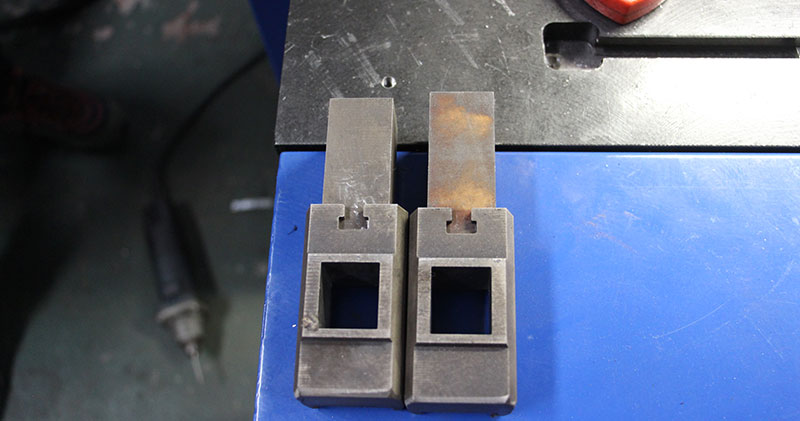

4. Professional middle mold design, easy to change

5. Air cooling system cools the hydraulic oil to ensure that the oil temperature is below 60 degrees, increasing the service life of the hydraulic components.

Technical Specification:

Machine bed | machine size | mm | 6500*1000*1580 |

Table size | mm | 350*200 | |

Gantry steel plate thickness | mm | 40 | |

Frame pipe size | mm | 160*80*4 / 80*80*3 | |

Machine weight | Kg | 2000 | |

Fuel tank capacity | L | 100 | |

Carrier aircraft | ------ | roller | |

Hydraulic system | Main motor | kw | 380v11kw |

The oil pump | ------ | Vane pump | |

Solenoid valve | ------ | DSG-03 | |

Hydraulic cylinder | ------ | 125 (inner diameter) | |

Hydraulic cylinder stroke | mm | 100 | |

Output pressure | Kn | 160~180 | |

Cooling system | ------ | 150L Air-cooled | |

Feeding system | Display | ------ | 7” touch screen |

Servo motor | ------ | 0.75kw | |

Gear and rack | grade | GB6 | |

Reducer | ------ | planetary reducer | |

clamp | ------ | Pneumatic clamp | |

guide | ------ | linear guide | |

mold | The mold material | ------ | DC53/Japan |

The mold hardness | HRC | 60-63 | |

Mould Accessory | ------ | Bearing edge protection |